Flycutting

Ultra-precise turning using diamond

What is flycutting

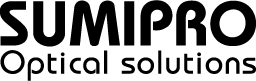

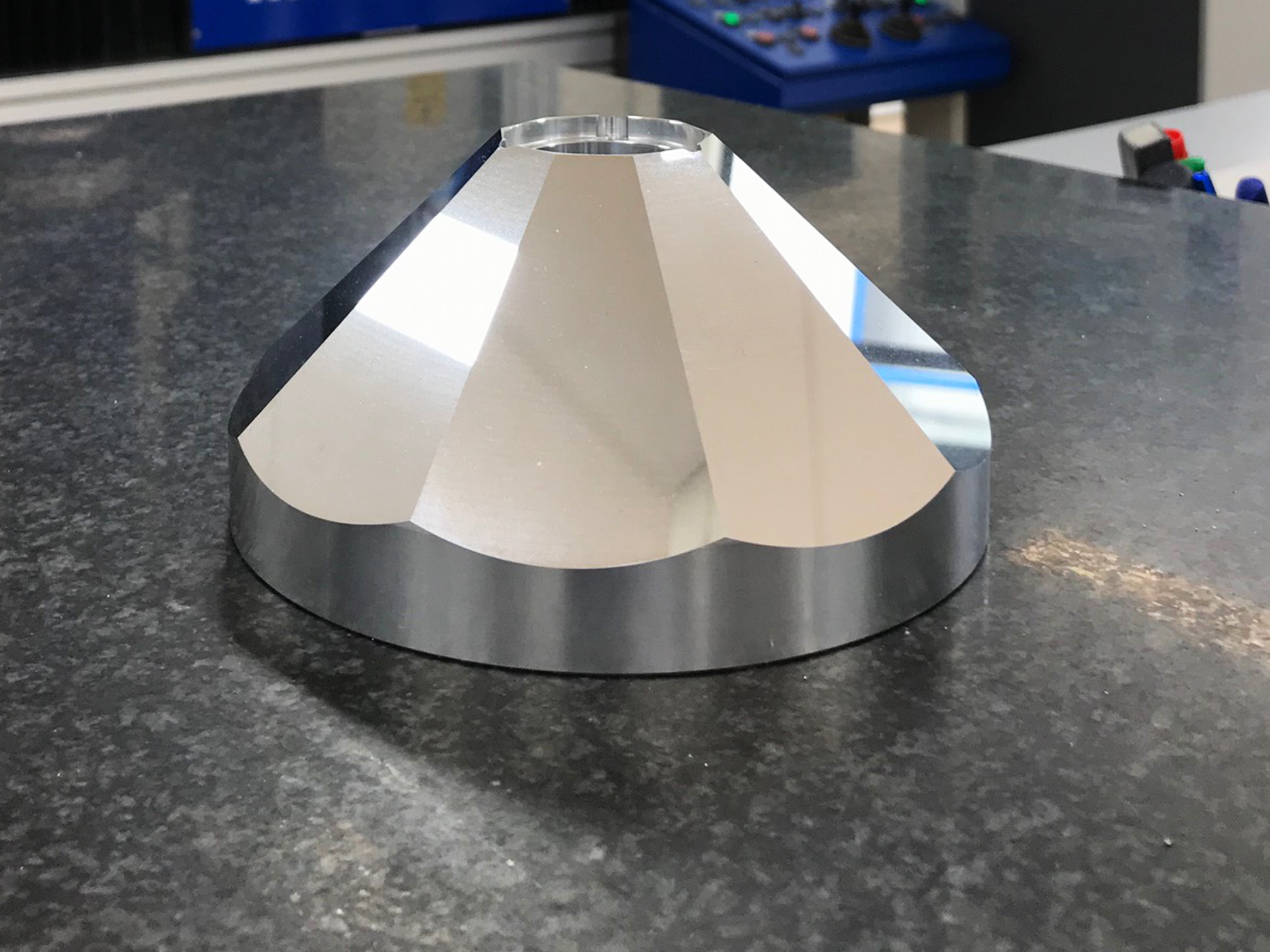

Fly-cutting is a process in which the diamond tool tip is on an air bearing spindle and is rotating very fast. The object is in rest with respect to the rotating spindle and with a specific tooltip geometry very flat optical surfaces can be realized. As with diamond turning, the same materials can be used for creating optics and also designers can use the full CNC capabilities of metal turning and milling, as long as the surface to be diamond turned is in range of the fly-cutter. This gives a distinctive advantage to assembly later on. The ultra precision (UP) machines manufactured by LT Ultra are used to prepare non-ferrous materials for optical-grade laser equipment. However, we are not limited to that: We can create precise surfaces on the most delicate of structures. Examples include air bearings and high precision tooling.

Materials that can be processed by flycutting:

Non-ferrous metals: Aluminum, copper, brass, nickel.

Plastics: PMMA, PC, Zeonex, Topaz, OKP, APL, etc.

IR lens materials: Silicon, germanium.

Part sizes: 1 – 300 mm.

Shapes: flat, polygons, angled surfaces.

Optical requirements (ISO 10110):

Shape accuracy (PV): < 100 nm, depending on diameter, material and geometry.

Shape accuracy (RMS): < 15 nm, depending on diameter, material and geometry.

Surface roughness (Rq): down to 2 nm, depending on material.

Products

Examples of our products